Injection Moulding Nottingham

Injection Moulding

Injection Moulding is a great option if you wish to produce the same item time and time again. Once the mould has been produced to your exact specifications with our 3d printer, it can be used for many years to exactly replicate the last item. This can be extremely cost effective for many commercial operations, big or small! From artisan cottage industry to far larger production companies, injection moulding is well worth considering. Our 3d printing consultants can fully discuss this option with you, as well as the cost saving, long term advantages. We can also provide you with an injection moulding quote, you will probably be surprised to find out how cheap 3d printing services can be! For any regular or large scale productions, injection moulding will often be the answer you are looking for!

Injection Moulding enquiry

What is Injection Moulding?

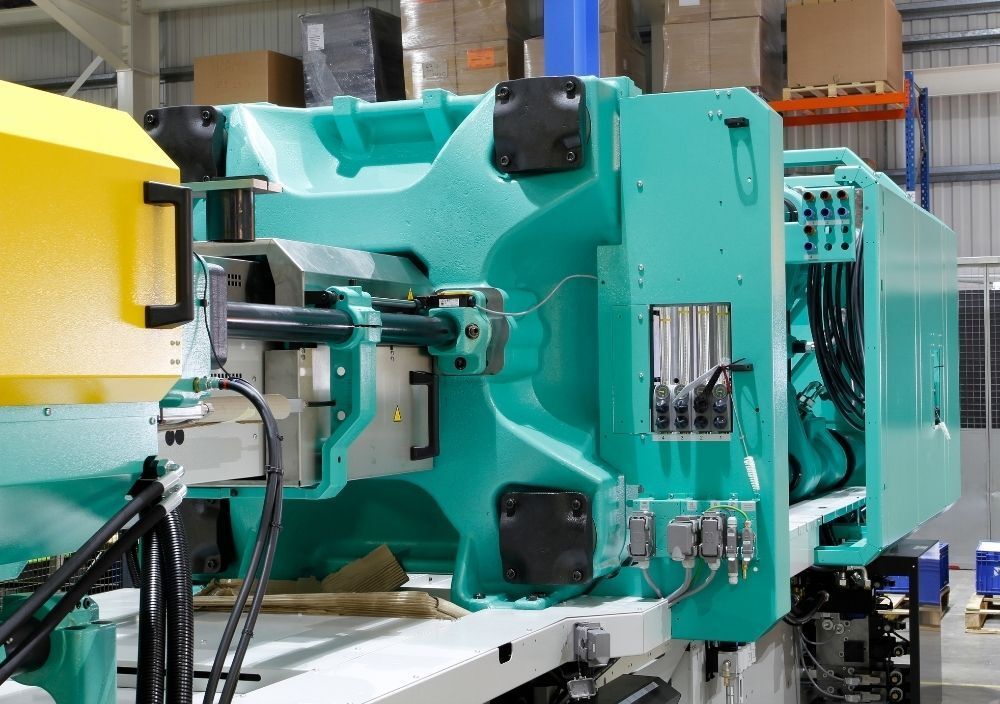

Injection moulding in very simple terms is a means of creating a product by injecting hot molten materials, mostly plastic, into a pre-designed mould. When the plastic cools it solidifies, which enables the mould to be opened and the finished product can be taken out of the mould. This is a fast production process and is normally used when a large number of an identical product are required. As mentioned, this is a great production process for large runs of a product as there is a large upfront cost associated with the creation of the mould but, by producing many items this cost is divided over a large number of units thereby making the 'cost per unit' much cheaper and effective for volume production. Some types of design shapes - size combined with intricacy may not be appropriate for this method of production but this will be highlighted by our team before any mould construction work takes place.

How do you create the Perfect Injection Mould?

As with all 3d design projects your mould will be created in line with your exact specifications. We will listen to all of your requirements throughout the consultation process and then design the perfect mould to meet your needs. As with all other 3d printing projects we will present you with a CAD 3d model for your approval before we 3d print your new mould, or moulds. The digital data of this design will then be processed by our rapid prototyping or CNC equipment. The production will then begin. Once complete we can deliver an excellent injection moulding service on your behalf, or you are free to take the moulds away with you. Whichever best suits you!

Which Materials do you use to create the Perfect Mould?

Hard grade Steel is a common, and probably the most popular choice for the creation of long lasting and reliable moulds. Producing a 3d print metal mould is ideal and can allow for more design variations. Its outstanding qualities deliver excellent results but other options are also equally suitable for many projects. There are a wide range of plastics available, a flexible plastic mould can make the removal of your finished moulding far easier and prevent any damage occurring. We can provide full assistance when choosing a suitable material for your injection moulding.

Plastic Injection Moulding Nottingham

Almost any material can be used: glass, metals, ceramics, composites as well as a wide range of plastics and resins are all suitable for injection moulding. Whichever product is suitable for your design, it is highly likely it can be used. That said, the most common by far is plastic injection moulding in Nottingham. Due to the variety of plastics available from rigid, to fire retardant to rubber-like the use of plastics for injection moulding dwaft the other material options.

Need help?

Frequently Asked Questions